Finest Practices for Preventing Weld Undercut: Mastering the Fundamentals

Finest Practices for Preventing Weld Undercut: Mastering the Fundamentals

Blog Article

Understanding the Art of Welding: How to Avoid Undercut Welding Issues for Flawless Manufacture Results

By recognizing the origin causes of undercut welding and carrying out effective methods to stop it, welders can raise their craft to brand-new degrees of quality. In the quest of perfect construction results, grasping the art of welding to avoid undercut issues is not just a skill however a necessity for those aiming for perfection in their work.

Understanding Undercut Welding

To stop undercut welding, welders need to guarantee proper welding criteria, such as readjusting the present, voltage, traveling rate, and keeping the right electrode angle. Furthermore, utilizing the appropriate welding method for the specific joint configuration is vital. Using weaving movements or backstepping techniques can help make sure proper weld steel deposition and decrease the possibility of undercut development. Routine assessment of welds during and after the welding procedure is likewise critical to capture any undercut early and make essential changes to avoid further flaws. Preventing weld undercut. By recognizing the root causes of undercut welding and implementing safety nets, welders can accomplish top quality, structurally audio welds.

Root Causes Of Undercut in Welding

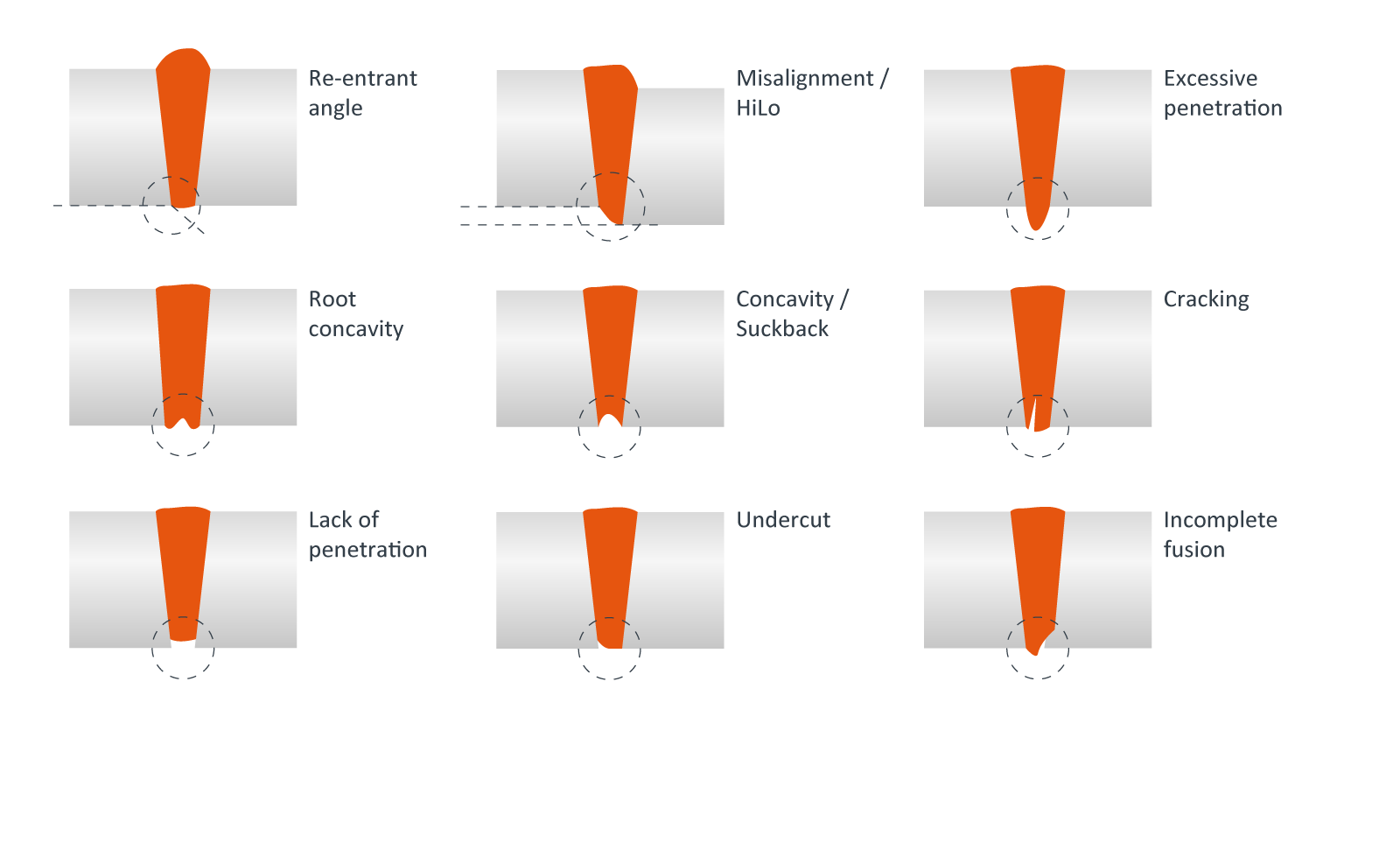

Comprehending the factors that add to undercut in welding is vital for welders to create top notch, structurally audio welds. Damaging occurs when the weld steel does not effectively fill the groove created between the base steel and the formerly transferred weld steel. Numerous factors can bring about damage in welding. One typical reason is extreme heat input. Welding at high temperatures for extensive periods can cause the base steel melting even more than preferred, causing undercut. Insufficient welding current or wrong welding speed can likewise add to undercut. Not enough current may not provide enough warm to thaw the base and filler steels properly, while too much rate can stop proper fusion, triggering undercut. Additionally, incorrect electrode angles or inaccurate lantern adjustment techniques can create areas of reduced weld steel deposition, promoting undercut. Understanding these reasons and implementing proper welding methods can aid protect against damaging concerns, making certain sturdy and solid welds.

Methods to avoid Undercutting

To reduce the threat of undercutting in welding, welders can use strategic welding strategies intended at improving the high quality and stability of the weld joints. In addition, utilizing the proper welding method for the specific joint configuration, such as weave or stringer grains, can add to Read Full Report decreasing undercutting.

Utilizing back-step welding techniques and regulating the weld bead account can additionally assist distribute warmth equally and lessen the danger of undercut. Routine assessment of the weld joint during and after welding, as well as carrying out top quality assurance measures, can help in identifying and addressing undercutting concerns quickly.

Value of Correct Welding Criteria

Selecting and keeping ideal welding specifications is important for accomplishing effective welds with minimal flaws. Welding parameters describe variables such as voltage, existing, travel speed, electrode angle, and shielding gas flow rate that directly affect the welding process. These specifications must be carefully changed based on the sort of material being welded, its thickness, and the welding technique utilized.

Proper welding parameters make certain the correct amount of warmth look at more info is used to thaw the base metals and filler product evenly. If the specifications are set too high, it can bring about too much warmth input, causing spatter, distortion, or burn-through. On the various other hand, if the specifications are also reduced, insufficient combination, absence of penetration, or damaging may take place.

Quality Control in Welding Operations

Verdict

Finally, grasping the art of welding needs a detailed understanding of undercut welding, its reasons, and strategies to avoid it. By ensuring proper welding specifications and carrying out high quality assurance methods, perfect manufacture results can be attained. It is essential for welders to regularly make important site every effort for quality in their welding operations to prevent undercut issues and generate top notch welds.

Undercut welding, an usual defect in welding procedures, occurs when the weld metal doesn't properly fill up the groove and leaves a groove or depression along the bonded joint.To avoid undercut welding, welders should guarantee proper welding parameters, such as changing the current, voltage, travel rate, and keeping the right electrode angle. Inadequate welding existing or incorrect welding speed can likewise contribute to damage.To reduce the risk of damaging in welding, welders can utilize strategic welding methods aimed at improving the top quality and honesty of the weld joints.In verdict, understanding the art of welding needs a complete understanding of undercut welding, its causes, and techniques to prevent it.

Report this page